Choisissez votre pays et votre langue

- Nederlands, Belgique / België

- Česky, Česká republika

- Deutsch, Deutschland

- Español, España

- Português, Portugal

- English, Europe

- Français, France

- Italiano, Italia

- Magyar, Magyarország

- Nederlands, Nederland

- Deutsch, Österreich

- Polski, Polska

- Română, România

- Suisse / Schweiz / Svizzera

- Svenska, Sverige

- Suomeksi, Suomi

- Türkçe, Türkiye

- English, United Kingdom

- Slovenská, Slovak

-

Worldwide

- Produits phares

- Produits par industrie

- Instruments de mesure à main et gestion de données

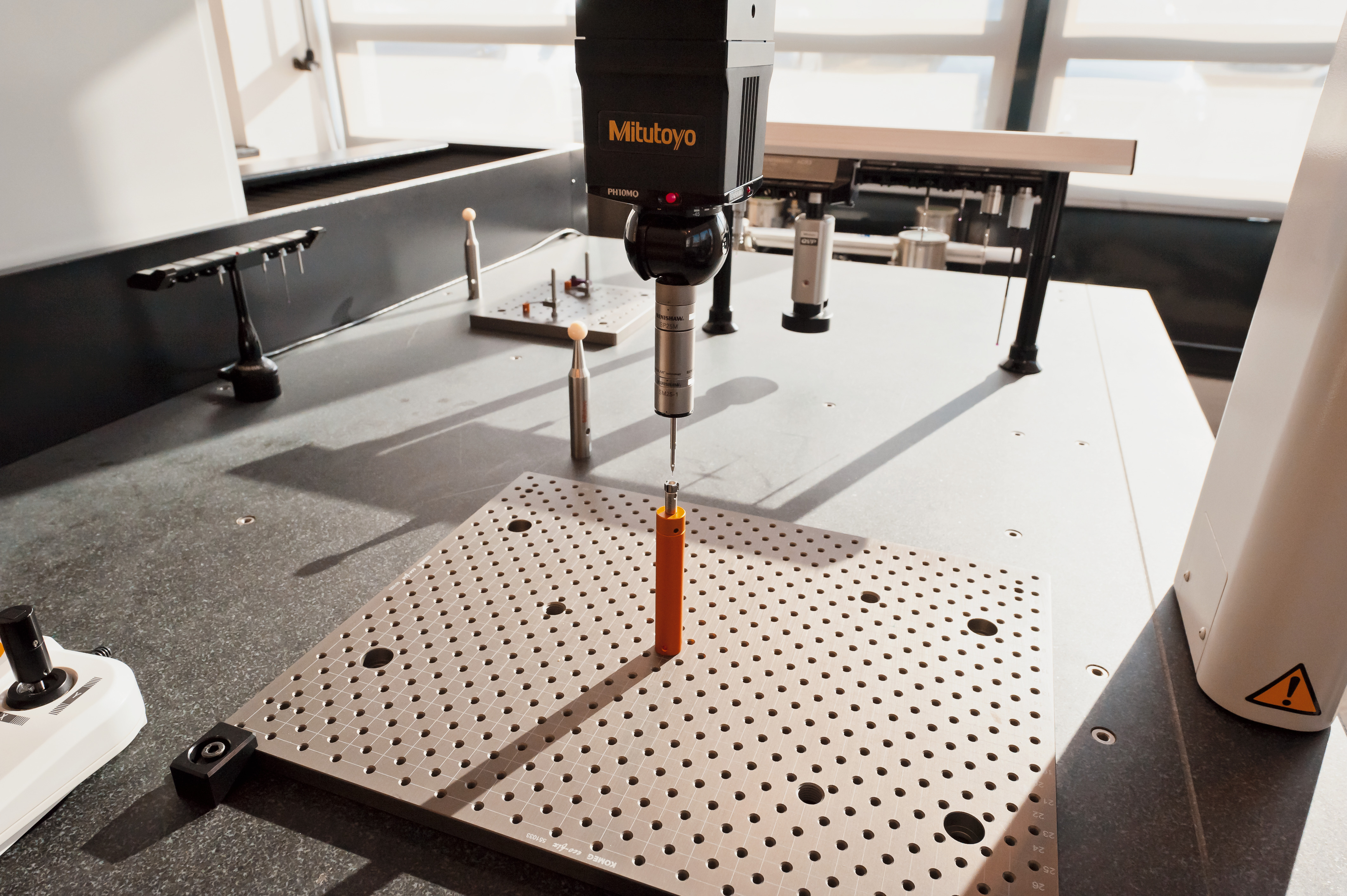

- Machine de mesure tridimensionnelle

- Machines de vision

- Mesure optique

- Mesure de forme

- Testeurs de dureté

- Linear Gage, afficheur de LG et Litematic

- Systèmes de mesure linéaire et compteurs

- Gestion de données

- Logiciel

- Tomographie

- Produits phares

- QM-Fit

- SmartMeasure-AL

- SJ-220

- Measurlink 10

- Série HR-600

- QuantuMike

- LEGEX Takumi

- STRATO-Active

- TAGLENS

- MCOSMOS 5

- Crysta Apex V

- Formtracer Avant

- MiSTAR 555

- Pied à coulisse

- Transmission de données Bluetooth

- QuickVision Pro

- Produits par industrie

- Aérospatiale

- Medical

- Automobile

- Energie

- Fabrication générale

- Electronique

- Fabricants d'équipements d'origine (OEM)

- Etude de cas

- Instruments de mesure à main et gestion de données

- Pied à coulisse

- Micromètre et butée micrométrique

- Instrument de mesure d'intérieur

- Instrument de mesure de profondeur

- Colonne de mesure & trusquin

- Comparateur & comparateur à bras de palpage

- Equipements auxiliaires

- Etalonnage

- Cales

- Machine de mesure tridimensionnelle

- MMT de petites et moyennes dimensions

- MMT en ligne et d'atelier

- MMT de grandes dimensions

- Plateau rotatif MRT pour MMT

- Systèmes de palpage (MMT)

- Stylets et accessoires

- Bridages pour mesures sur MMT

- Cabine de protection

- Logiciels MMT

- Machines de vision

- Quick Image Machine de vision 2D

- Quick scope Machine de vision automatisée

- Machines de mesure par analyse d'image 3D CNC Quick vision

- Quick vision Hybrid - Multi-capteurs 3D à balayage CNC

- MiSCAN Vision - Multi-capteurs tactile scanning continu

- QV UMAP - Multi-capteurs tactiles pour micro-géométrie

- Logiciels Vision

- Accessoires pour machines de vision

- Bridage de mesures sur appareil optique

- Stylets et accessoires

- Mesure optique

- Loupes

- Projecteurs de profil

- Microscopes de mesure

- Unités de microscopes

- Interferometer Units

- Oculaires et objectifs

- Accessoires pour microscopes et projecteurs

- TAGLENS

- Bridages appareils optiques

- Mesure de forme

- Rugosimètre

- Appareils de mesure de profils Contracer

- Appareils de mesure d'état de surface et de contour Formtracer

- Contrôle de cylindricité Roundtest

- Logiciels pour produits de forme

- Bridage

- Testeurs de dureté

- Testeur de dureté portable (HH-300/HH-411)

- Rockwell, Rockwell Superficiel, Brinell

- Testeur de dureté Vickers série HV

- Testeur de dureté automatisé Vickers/Micro-Vickers

- Testeur de dureté Micro-Vickers Série HM

- Logiciel pour testeur de dureté

- Accessoires de dureté et pénétrateurs

- Linear Gage, afficheur de LG et Litematic

- Linear Gage Digimatic et incrémental

- Mesureur vertical à faible pression de mesure LITEMATIC

- Compteurs et afficheurs pour Linear Gage

- Micromètres à balayage laser

- Surface Measure 1008S

- Logiciel pour Linear Gage

- Systèmes de mesure linéaire et compteurs

- Règles de visualisation et Compteurs KA

- Règles de visualisation

- Règles horizontales et verticales

- Pied à coulisse

- Pied à coulisse

- Pied à coulisse Absolute Digimatic

- Pied à coulisse spécial

- Pied à coulisse mécanique

- Accessoires pour pieds à coulisse

- Micromètre et butée micrométrique

- Micromètre Digimatic et mécanique

- Accessoires pour micromètres

- Butée micrométrique

- Support pour butées

- Instrument de mesure d'intérieur

- Micromètre d'intérieur

- Vérificateurs d'alésage

- Accessoires pour instruments de mesure d'intérieur

- Instrument de mesure de profondeur

- Jauge de profondeur micrométrique

- Jauge de profondeur

- Accessoires jauges de profondeur

- Comparateur & comparateur à bras de palpage

- Comparateur Digimatic ABSOLUTE

- Accessoires pour comparateurs : touches, embases, rallonges, dos...

- Comparateur à palpeur orientable

- Comparateur mécanique

- Accessoires pour comparateurs orientables

- Jauge d'épaisseur

- Equipements auxiliaires

- Bases

- Etaux

- Plaques sinus marbres

- Rapporteurs d'angles

- Jauges d'épaisseur, réglets

- Etalonnage

- Micromètre Height Masters Universel

- Calibre de réglage/ contrôle & Check Masters

- Instruments d'étalonnage (Etalon, équerre, pige, règle en verre...)

- Cales

- Jeu de cales acier

- Cale individuelle acier

- Jeu de cales céramiques

- Cale individuelle céramique

- Cales spéciales (CDT étalonné, zéro Cera)

- Accessoires pour cales de jauge

- Accessoires pour cales (support, entretien, Ceraston)

- MMT de petites et moyennes dimensions

- CRYSTA-Apex V - 500/700/900

- CRYSTA-Apex V - 1200/1600/2000

- CRYSTA-Apex EX 1200R

- STRATO-Active

- STRATO-Apex - 500/700/900

- STRATO-Apex - 1600

- LEGEX

- MMT de grandes dimensions

- STRATO Apex G

- Machine de mesure tridimensionnelle CARB pour la mesure de pièces très volumineuses

- Stylets et accessoires

- Stylets

- Stylets droits

- Stylets revêtus de diamant

- Stylets en diamant très résistant

- Stylets étalon

- Stylets pour machine outil

- Stylets étoile

- Stylets 5 directions

- Stylets sans filetage

- Stylets cylindriques

- Stylets à disque

- Stylets en pointe

- Rallonges

- Supports

- Adaptateurs

- Genouillères

- Vis pour cube

- Outils

- StyliCleaner pour le nettoyage des stylets

- Bridages pour mesures sur MMT

- Kit de bridage pour MMT

- Kit de palettisation eco-fix PRS

- Logiciel FixtureBuilder pour eco-fix

- Extension de jeu eco-fix/eco-fix plus

- Eléments eco-fix et eco-fix plus

- Vis et outils

- Machines de mesure par analyse d'image 3D CNC Quick vision

- Quick Vision ACTIVE

- Quick Vision APEX / HYPER

- Quick Vision ACCEL

- Quick Vision ULTRA

- MiSCAN Vision - Multi-capteurs tactile scanning continu

- MiSCAN APEX 404

- MiSCAN HYPER 302

- MiSCAN HYPER 404

- Bridage de mesures sur appareil optique

- Kit de bridage opti-fix pour mesure optique

- Composants opti-fix

- Vis et outils

- Stylets et accessoires

- Stylets droits

- Rallonges

- Stylets étoile

- Supports

- Stylets 5 directions

- Stylets sans filetage

- Adaptateurs

- Genouillères

- Stylets cylindriques

- Stylets à disque

- Stylets en pointe

- Vis pour cube

- Outils

- Jeux de stylets

- Projecteurs de profil

- Projecteur de profil PJ

- Projecteur de profil PV

- Projecteur de profil PH

- Calculateur QM-Data 200

- Accessoires pour projecteurs de profil

- Règles graduées en verre

- Microscopes de mesure

- Microscope de mesure TM génération B

- Microscope de mesure standard série MF

- Microscopes de mesure universels série MF-U

- Sources d'éclairage en option pour microscopes de mesure MF-D/MF-UD

- Vision Unit

- Logiciel QSPAK-VUE

- Caméras pour microscopes

- Oculaires et objectifs

- Objectif de correction fini série ML

- Observation champ clair

- Objectif pour observation champ clair / sombre

- Objectifs NIR

- Objectifs NIR LCD

- Objectifs NUV

- Objectifs NUV LCD

- Objectifs UV

- Objectifs UV LCD

- Interférométre

- Bridages appareils optiques

- Kit de bridage opti-fix pour mesure optique

- Composants Opti-fix

- Vis et outils pour opti-fix

- Rugosimètre

- Surftest SJ-210

- Surftest SJ-220

- Surftest SJ-310

- Surftest SJ-410

- Surftest SJ-500

- Surftest SV-2100

- Surftest SJ-500P

- Surftest SV-2100P

- Formtracer Avant FTA-S3000

- Surftest Extreme SV-3000CNC

- Surftest Extreme SV-M3000CNC

- Appareils de mesure d'état de surface et de contour Formtracer

- Formtracer Avant FTA-D3000 / FTA-D4000

- Formtracer CS-3300

- Formtracer Extreme SV-C4500CNC

- Formtracer Extreme SV-C4500CNC HYBRID Type 1

- Formtracer Extreme CS-5000CNC et CS-H5000CNC

- Testeur de dureté portable (HH-300/HH-411)

- Testeur de dureté portatif HARDMATIC HH-411

- Duromètres numériques et analogiques HARDMATIC HH-300

- Rockwell, Rockwell Superficiel, Brinell

- Testeur de dureté Rockwell HR-100/200/300/400

- Testeurs de dureté Wizhard pour Rockwell, Rockwell Superficiel, Brinell Série HR-530

- Testeur de dureté Rockwell automatique HR-600

- Testeur de dureté automatisé Vickers/Micro-Vickers

- Testeurs de dureté automatique Micro-Vickers

- Testeurs de dureté automatique Vickers

- Linear Gage Digimatic et incrémental

- Linear Gage ABSOLUTE Digimatic LGS

- Entraînement pneumatique

- Linear Gage LG100

- Linear Gage LG200 Series

- Laser Hologage

- Mesureur vertical à faible pression de mesure LITEMATIC

- LITEMATIC VL-50 Mesureur vertical à faible pression de mesure

- Compteurs et afficheurs pour Linear Gage

- Compteur EJ pour Linear Gage

- Compteur EC pour Linear Gage LGD et LGS

- Compteur EG pour Linear Gage

- Compteur EH pour Linear Gage

- Compteur EV pour Linear Gages

- Unité d'affichage pour compteur EV

- Micromètres à balayage laser

- Micromètre à balayage laser sans afficheur LSM 02-A/30

- Contrôleur pour LSM-02-A (544-123) et LSM-30-A (544-124)

- Interface pour LSM-02-A / LSM-30-A

- Micromètre à balayage laser - Accessoires en option

- Règles de visualisation et Compteurs KA

- Règle de visualisation AT103

- Règle de visualisation AT103 - Haute précision

- Règle de visualisation Linear Scale AT113

- Règle de visualisation Linear Scale AT113 - Haute précision

- Règle de visualisation ABS. Linear Scale AT715

- Compteur KA

- Règles de visualisation

- Règle de visualisation ST36

- Règle de visualisation Linear Scales ST46-EZA

- NC Linear Scales ABS ST700

- NC Linear Scales ABS ST1300

- NC Linear Scales AT211

- NC Linear Scales ABS AT1100

- NC Linear Scales ABS AT1300

- Règles horizontales et verticales

- Système de mesure Absolute étanche modèle horizontal

- Système de mesure Absolute Digimatic Modèle standard horizontal

- Système de mesure Absolute Digimatic modèle horizontal multifonctions avec inversion du sens du comptage

- Système de mesure Absolute Digimatic modèle horizontal multifonctions fonction diamètre

- Système de mesure Absolute Digimatic modèle vertical standard

- Système de mesure Absolute Digimatic modèle vertical multifonctions inversion du sens de comptage

- Système de mesure Absolute Digimatic modèle vertical multifonctions fonction diamètre

- Multiplexeurs & Interfaces

- Interface Digimatic-USB / Interface clavier

- Multiplexeur DMT-3T / FS2 USB

- Multiplexeur DMX-1 USB

- Multiplexeur DMX-2 S

- Multiplexeur DMX-2 USB

- Multiplexeur DMX-3 USB

- Multiplexeur MUX-10F

- Multiplexeur DMX-8/2

- Multiplexeur DMX-16 / DMX-16C

- Multiplexeur DMX-0-1 USB / DMX-3-2 USB

Aérospatiale

Aérospatiale

Les applications aérospatiales complexes nécessitent un contrôle qualité rapide et extrêmement précis pour garantir des assemblages exacts. Découvrez comment Mitutoyo y parvient.

Automobile

Automobile

L'industrie automobile continue d'innover, et Mitutoyo offre des capacités d'inspection et de numérisation avancées pour aider les fabricants à atteindre une production continue.

Énergie

Énergie

Les solutions de mesure et d'analyse de Mitutoyo sont conçues pour aider les fournisseurs d'énergie à améliorer la fiabilité et à augmenter le temps de fonctionnement des équipements.

Médical

Médical

Pour protéger le bien-être des patients, les applications médicales nécessitent une précision exceptionnelle. Découvrez comment les solutions Mitutoyo largement testées peuvent vous aider à y parvenir.

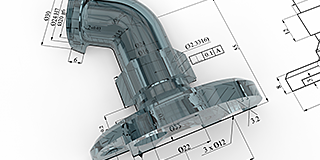

Fabrication générale

Fabrication générale

Garantissez une répétabilité élevée et un contrôle qualité rigoureux avec les solutions de mesure de forme, les machines de mesure tridimensionnelles et les outils de mesure de précision de Mitutoyo.

Électronique

Électronique

Les solutions de mesure sans contact et par vision de Mitutoyo apportent une précision microscopique aux composants électroniques plus petits et plus denses.

Fabricants d'équipements d'origine (OEM)

Fabricants d'équipements d'origine (OEM)

Mitutoyo OEM peut pallier le manque d'expertise ou de ressources en vous fournissant notre équipement de métrologie renommé qui s'intègre parfaitement à vos produits.

Études de cas

Études de cas

Pour un aperçu des capacités de Mitutoyo, il n'y a rien de mieux que notre merveilleuse collection d'études de cas.

Formation métrologie

Formation métrologie

Formations par des spécialistes dans nos locaux ou sur site couvrant tous les aspects de la métrologie. Référencé sur Datadock

Service après-vente

Service après-vente

Mitutoyo France dispose de deux services après-vente dédiés aux biens d'équipements et aux instruments à main.

Étalonnage

Étalonnage

Faites étalonner vos appareils de mesure par un laboratoire de confiance

Services sur site

Services sur site

Service sur site de vos machines de mesure et d'essai préférées.

Application et programmation

Application et programmation

Mitutoyo vous propose son son expertise pour la réalisation de vos programmes de mesure ou la délégation éventuelle d'un spécialiste sur votre site pour vous assister en cas de besoin.

Démonstrations de produits

Démonstrations de produits

En ligne ou hors ligne, obtenez une démonstration de produit dès aujourd'hui.

Assistance informatique

Assistance informatique

Installation et intégration parfaites et sans problème dans votre infrastructure informatique.

Siège Mitutoyo Japon

Siège Mitutoyo Japon

La première étape pour les entreprises japonaises opérant en Europe

Qualité

Qualité

Un service de qualité, reconnu et certifié.

Packs éducatifs

Packs éducatifs

Idéal pour les ateliers ou en salle de classe, il n'y a pas mieux que les affiches ou le matériel d'apprentissage Mitutoyo.

E-Learning

E-Learning

Pour ceux qui s'intéressent à la métrologie, Mitutoyo propose des cours d'apprentissage en ligne pour aider à former les étudiants, le personnel ou même les amateurs.

Découvrez Mitutoyo

Découvrez Mitutoyo

La plus grande entreprise de métrologie au monde.

Recrutement

Recrutement

Mitutoyo recherche constamment à recruter les meilleurs collaborateurs. Découvrez nos offres d'emplois.

Développement Durable

Développement Durable

Découvrez la contribution de Mitutoyo en matière de développement durable.

Événements

Événements

Restez informé des événements organisés dans toute l'Europe et venez découvrir les nouveautés Mitutoyo.

Articles de presse

Articles de presse

Consultez nos dernières nouvelles, mises à jour et ressources.

Logiciels

Logiciels

Téléchargez nos logiciels et nos mises à jour facilement et commodément.

Assistance

Assistance

Retrouvez une assistance à distance avec nos techniciens et formateurs.

Documentation

Documentation

Consultez et téléchargez notre catalogue, nos brochures de produits, etc.

Catalogue en ligne

Catalogue en ligne

Consultez notre gamme de produits dans notre catalogue en ligne !

Déclarations de conformité

Déclarations de conformité

Vous pouvez télécharger les versions complètes pour l'UE et le Royaume-Uni.

Fonds d'écran gratuits

Fonds d'écran gratuits

Téléchargez ici gratuitement les fonds d'écran officiels de Mitutoyo.

Matériel de communication sur la marque Mitutoyo

Matériel de communication sur la marque Mitutoyo

Ressources pour le personnel Mitutoyo et les fournisseurs externes.

-

Produits

- Retour Produits

- Produits

- Produits phares

- Produits par industrie

-

Instruments de mesure à main et gestion de données

- Retour Instruments de mesure à main et gestion de données Instruments de mesure à main et gestion de données

- Pied à coulisse

-

Micromètre et butée micrométrique

- Retour Micromètre et butée micrométrique Micromètre et butée micrométrique

- Micromètre Digimatic et mécanique

- Accessoires pour micromètres

- Butée micrométrique

- Support pour butées

-

Instrument de mesure d'intérieur

- Retour Instrument de mesure d'intérieur Instrument de mesure d'intérieur

- Micromètre d'intérieur

- Vérificateurs d'alésage

- Accessoires pour instruments de mesure d'intérieur

-

Instrument de mesure de profondeur

- Retour Instrument de mesure de profondeur Instrument de mesure de profondeur

- Jauge de profondeur micrométrique

- Jauge de profondeur

- Accessoires jauges de profondeur

-

Colonne de mesure & trusquin

- Retour Colonne de mesure & trusquin Colonne de mesure & trusquin

- Colonne de mesure

- Trusquin

- Accessoires pour trusquin

-

Comparateur & comparateur à bras de palpage

- Retour Comparateur & comparateur à bras de palpage Comparateur & comparateur à bras de palpage

- Comparateur Digimatic ABSOLUTE

- Accessoires pour comparateurs : touches, embases, rallonges, dos...

- Comparateur à palpeur orientable

- Comparateur mécanique

- Accessoires pour comparateurs orientables

- Jauge d'épaisseur

-

Equipements auxiliaires

- Retour Equipements auxiliaires Equipements auxiliaires

- Bases

- Etaux

- Plaques sinus marbres

- Rapporteurs d'angles

- Jauges d'épaisseur, réglets

- Etalonnage

- Cales

-

Machine de mesure tridimensionnelle

- Retour Machine de mesure tridimensionnelle Machine de mesure tridimensionnelle

-

MMT de petites et moyennes dimensions

- Retour MMT de petites et moyennes dimensions MMT de petites et moyennes dimensions

- CRYSTA-Apex V - 500/700/900

- CRYSTA-Apex V - 1200/1600/2000

- CRYSTA-Apex EX 1200R

- STRATO-Active

- STRATO-Apex - 500/700/900

- STRATO-Apex - 1600

- LEGEX

-

MMT en ligne et d'atelier

- Retour MMT en ligne et d'atelier MMT en ligne et d'atelier

- MACH Ko-ga-me

- MACH-3A 653

- MACH-V9106

- MiSTAR 555

- MMT de grandes dimensions

-

Plateau rotatif MRT pour MMT

- Retour Plateau rotatif MRT pour MMT Plateau rotatif MRT pour MMT

- Plateau rotatif MRT240

- Plateau rotatif MRT320

-

Systèmes de palpage (MMT)

- Retour Systèmes de palpage (MMT) Systèmes de palpage (MMT)

- SurfaceMeasure

- REVO

- SP80

- TP7M

-

Stylets et accessoires

- Retour Stylets et accessoires Stylets et accessoires

- Stylets

- Stylets droits

- Stylets revêtus de diamant

- Stylets en diamant très résistant

- Stylets étalon

- Stylets pour machine outil

- Stylets étoile

- Stylets 5 directions

- Stylets sans filetage

- Stylets cylindriques

- Stylets à disque

- Stylets en pointe

- Rallonges

- Supports

- Adaptateurs

- Genouillères

- Vis pour cube

- Outils

- StyliCleaner pour le nettoyage des stylets

- Bridages pour mesures sur MMT

-

Cabine de protection

- Retour Cabine de protection Cabine de protection

- Cabine de protection pour MMT

-

Logiciels MMT

- Retour Logiciels MMT Logiciels MMT

- MiCAT Planner

- MCOSMOS

- MAFIS Express

- MSURF

-

Machines de vision

- Retour Machines de vision Machines de vision

-

Quick Image Machine de vision 2D

- Retour Quick Image Machine de vision 2D Quick Image Machine de vision 2D

- Quick Image

- Logiciel Quick Image

-

Quick scope Machine de vision automatisée

- Retour Quick scope Machine de vision automatisée Quick scope Machine de vision automatisée

- Quick Scope QS-L automatisée

- Logiciel Quick Scope

-

Machines de mesure par analyse d'image 3D CNC Quick vision

- Retour Machines de mesure par analyse d'image 3D CNC Quick vision Machines de mesure par analyse d'image 3D CNC Quick vision

- Quick Vision ACTIVE

- Quick Vision APEX / HYPER

- Quick Vision ACCEL

- Quick Vision ULTRA

-

Quick vision Hybrid - Multi-capteurs 3D à balayage CNC

- Retour Quick vision Hybrid - Multi-capteurs 3D à balayage CNC Quick vision Hybrid - Multi-capteurs 3D à balayage CNC

- Quick Vision Hybrid

- Quick Vision WLI

-

MiSCAN Vision - Multi-capteurs tactile scanning continu

- Retour MiSCAN Vision - Multi-capteurs tactile scanning continu MiSCAN Vision - Multi-capteurs tactile scanning continu

- MiSCAN APEX 404

- MiSCAN HYPER 302

- MiSCAN HYPER 404

-

QV UMAP - Multi-capteurs tactiles pour micro-géométrie

- Retour QV UMAP - Multi-capteurs tactiles pour micro-géométrie QV UMAP - Multi-capteurs tactiles pour micro-géométrie

- UMAP Vision Systems

- Logiciel UMAP

-

Logiciels Vision

- Retour Logiciels Vision Logiciels Vision

- QVPAK

- QSPAK

- QIPAK

- Accessoires pour machines de vision

-

Bridage de mesures sur appareil optique

- Retour Bridage de mesures sur appareil optique Bridage de mesures sur appareil optique

- Kit de bridage opti-fix pour mesure optique

- Composants opti-fix

- Vis et outils

- Stylets et accessoires

-

Mesure optique

- Retour Mesure optique Mesure optique

- Loupes

- Projecteurs de profil

- Microscopes de mesure

-

Unités de microscopes

- Retour Unités de microscopes Unités de microscopes

- Unité de microscope FS-70

- Unité de microscope vidéo VMU

- Interferometer Units

- Oculaires et objectifs

- Accessoires pour microscopes et projecteurs

- TAGLENS

-

Bridages appareils optiques

- Retour Bridages appareils optiques Bridages appareils optiques

- Kit de bridage opti-fix pour mesure optique

- Composants Opti-fix

- Vis et outils pour opti-fix

-

Mesure de forme

- Retour Mesure de forme Mesure de forme

- Rugosimètre

-

Appareils de mesure de profils Contracer

- Retour Appareils de mesure de profils Contracer Appareils de mesure de profils Contracer

- Contracer CV-2100

- Formtracer Avant FTA-C3000 et FTA-C4000

-

Appareils de mesure d'état de surface et de contour Formtracer

- Retour Appareils de mesure d'état de surface et de contour Formtracer Appareils de mesure d'état de surface et de contour Formtracer

- Formtracer Avant FTA-D3000 / FTA-D4000

- Formtracer CS-3300

- Formtracer Extreme SV-C4500CNC

- Formtracer Extreme SV-C4500CNC HYBRID Type 1

- Formtracer Extreme CS-5000CNC et CS-H5000CNC

-

Contrôle de cylindricité Roundtest

- Retour Contrôle de cylindricité Roundtest Contrôle de cylindricité Roundtest

- Roundtest

- Roundtracer

-

Logiciels pour produits de forme

- Retour Logiciels pour produits de forme Logiciels pour produits de forme

- Formtracepak

- Roundpak

-

Bridage

- Retour Bridage Bridage

- Kits Eco-fix FMI

-

Testeurs de dureté

- Retour Testeurs de dureté Testeurs de dureté

-

Testeur de dureté portable (HH-300/HH-411)

- Retour Testeur de dureté portable (HH-300/HH-411) Testeur de dureté portable (HH-300/HH-411)

- Testeur de dureté portatif HARDMATIC HH-411

- Duromètres numériques et analogiques HARDMATIC HH-300

- Rockwell, Rockwell Superficiel, Brinell

-

Testeur de dureté Vickers série HV

- Retour Testeur de dureté Vickers série HV Testeur de dureté Vickers série HV

- HV-110/120 Vickers

-

Testeur de dureté automatisé Vickers/Micro-Vickers

- Retour Testeur de dureté automatisé Vickers/Micro-Vickers Testeur de dureté automatisé Vickers/Micro-Vickers

- Testeurs de dureté automatique Micro-Vickers

- Testeurs de dureté automatique Vickers

-

Testeur de dureté Micro-Vickers Série HM

- Retour Testeur de dureté Micro-Vickers Série HM Testeur de dureté Micro-Vickers Série HM

- Testeur de dureté Micro-Vickers HM-210/220

-

Logiciel pour testeur de dureté

- Retour Logiciel pour testeur de dureté Logiciel pour testeur de dureté

- AVPAK

-

Accessoires de dureté et pénétrateurs

- Retour Accessoires de dureté et pénétrateurs Accessoires de dureté et pénétrateurs

- Equipements de dureté

- Pénétrateurs et billes de remplacement

-

Linear Gage, afficheur de LG et Litematic

- Retour Linear Gage, afficheur de LG et Litematic Linear Gage, afficheur de LG et Litematic

-

Linear Gage Digimatic et incrémental

- Retour Linear Gage Digimatic et incrémental Linear Gage Digimatic et incrémental

- Linear Gage ABSOLUTE Digimatic LGS

- Entraînement pneumatique

- Linear Gage LG100

- Linear Gage LG200 Series

- Laser Hologage

-

Mesureur vertical à faible pression de mesure LITEMATIC

- Retour Mesureur vertical à faible pression de mesure LITEMATIC Mesureur vertical à faible pression de mesure LITEMATIC

- LITEMATIC VL-50 Mesureur vertical à faible pression de mesure

- Compteurs et afficheurs pour Linear Gage

- Micromètres à balayage laser

-

Surface Measure 1008S

- Retour Surface Measure 1008S Surface Measure 1008S

- Surface Measure 1008S

- Surface Measure 0303S

- Accessoires

- Logiciel pour Linear Gage

-

Systèmes de mesure linéaire et compteurs

- Retour Systèmes de mesure linéaire et compteurs Systèmes de mesure linéaire et compteurs

-

Règles de visualisation et Compteurs KA

- Retour Règles de visualisation et Compteurs KA Règles de visualisation et Compteurs KA

- Règle de visualisation AT103

- Règle de visualisation AT103 - Haute précision

- Règle de visualisation Linear Scale AT113

- Règle de visualisation Linear Scale AT113 - Haute précision

- Règle de visualisation ABS. Linear Scale AT715

- Compteur KA

- Règles de visualisation

-

Règles horizontales et verticales

- Retour Règles horizontales et verticales Règles horizontales et verticales

- Système de mesure Absolute étanche modèle horizontal

- Système de mesure Absolute Digimatic Modèle standard horizontal

- Système de mesure Absolute Digimatic modèle horizontal multifonctions avec inversion du sens du comptage

- Système de mesure Absolute Digimatic modèle horizontal multifonctions fonction diamètre

- Système de mesure Absolute Digimatic modèle vertical standard

- Système de mesure Absolute Digimatic modèle vertical multifonctions inversion du sens de comptage

- Système de mesure Absolute Digimatic modèle vertical multifonctions fonction diamètre

-

Gestion de données

- Retour Gestion de données Gestion de données

-

Logiciel d'analyses statistiques SPC

- Retour Logiciel d'analyses statistiques SPC Logiciel d'analyses statistiques SPC

- MeasurLink 10

- USB-ITPAK

-

Mini Processeur Digimatic

- Retour Mini Processeur Digimatic Mini Processeur Digimatic

- Imprimante Digimatic DP-1VA

- Câbles

-

Transmission de données sans fil U-Wave

- Retour Transmission de données sans fil U-Wave Transmission de données sans fil U-Wave

- U-WAVE fit

- U-WAVE Bluetooth

- Câbles de connexion U-WAVE-T

-

Multiplexeurs & Interfaces

- Retour Multiplexeurs & Interfaces Multiplexeurs & Interfaces

- Interface Digimatic-USB / Interface clavier

- Multiplexeur DMT-3T / FS2 USB

- Multiplexeur DMX-1 USB

- Multiplexeur DMX-2 S

- Multiplexeur DMX-2 USB

- Multiplexeur DMX-3 USB

- Multiplexeur MUX-10F

- Multiplexeur DMX-8/2

- Multiplexeur DMX-16 / DMX-16C

- Multiplexeur DMX-0-1 USB / DMX-3-2 USB

-

Timerbox, boîtier de transfert de données, boîtier de commutation

- Retour Timerbox, boîtier de transfert de données, boîtier de commutation Timerbox, boîtier de transfert de données, boîtier de commutation

- Timerbox

- Boîtier de commutation Digimatic

-

Logiciel

- Retour Logiciel Logiciel

-

Logiciels MMT

- Retour Logiciels MMT Logiciels MMT

- MiCAT Planner

- MCOSMOS

- MAFIS-Express

- MSURF

-

Logiciels Vision

- Retour Logiciels Vision Logiciels Vision

- QVPAK

- QSPAK

- QIPAK

-

Logiciels pour produits de forme

- Retour Logiciels pour produits de forme Logiciels pour produits de forme

- Formtracepak

- Roundpak

- Logiciels pour testeur de dureté

- Logiciel pour Linear Gage

-

Logiciel d'analyses statistiques SPC

- Retour Logiciel d'analyses statistiques SPC Logiciel d'analyses statistiques SPC

- Measurlink 10

- USB-ITPAK

- Tomographie

- Industrie

-

Services

- Retour Services

- Services

-

Formation métrologie

- Retour Formation métrologie

- Formation métrologie

- Service après-vente

- Étalonnage

- Services sur site

-

Application et programmation

- Retour Application et programmation

- Application et programmation

- Démonstrations de produits

- Assistance informatique

- Siège Mitutoyo Japon

- Qualité

-

Éducation

- Retour Éducation

- Éducation

- Packs éducatifs

- E-Learning

-

Nous / Recrutement

- Retour Nous / Recrutement

- Nous / Recrutement

-

Découvrez Mitutoyo

- Retour Découvrez Mitutoyo

- Découvrez Mitutoyo

- Nom & philosophie

- Société Mitutoyo

- Mitutoyo France

- Mitutoyo en Europe

-

Mitutoyo 90e anniversaire

- Retour Mitutoyo 90e anniversaire

- Mitutoyo 90e anniversaire

-

Histoire de Mitutoyo

- Retour Histoire de Mitutoyo

- Histoire de Mitutoyo

- Certifications & Accreditations

- Légitimité des produits (contrefaçon)

- Recrutement

- Développement Durable

-

Actualités

- Retour Actualités

- Actualités

-

Événements

- Retour Événements

- Événements

- Articles de presse

- Téléchargements

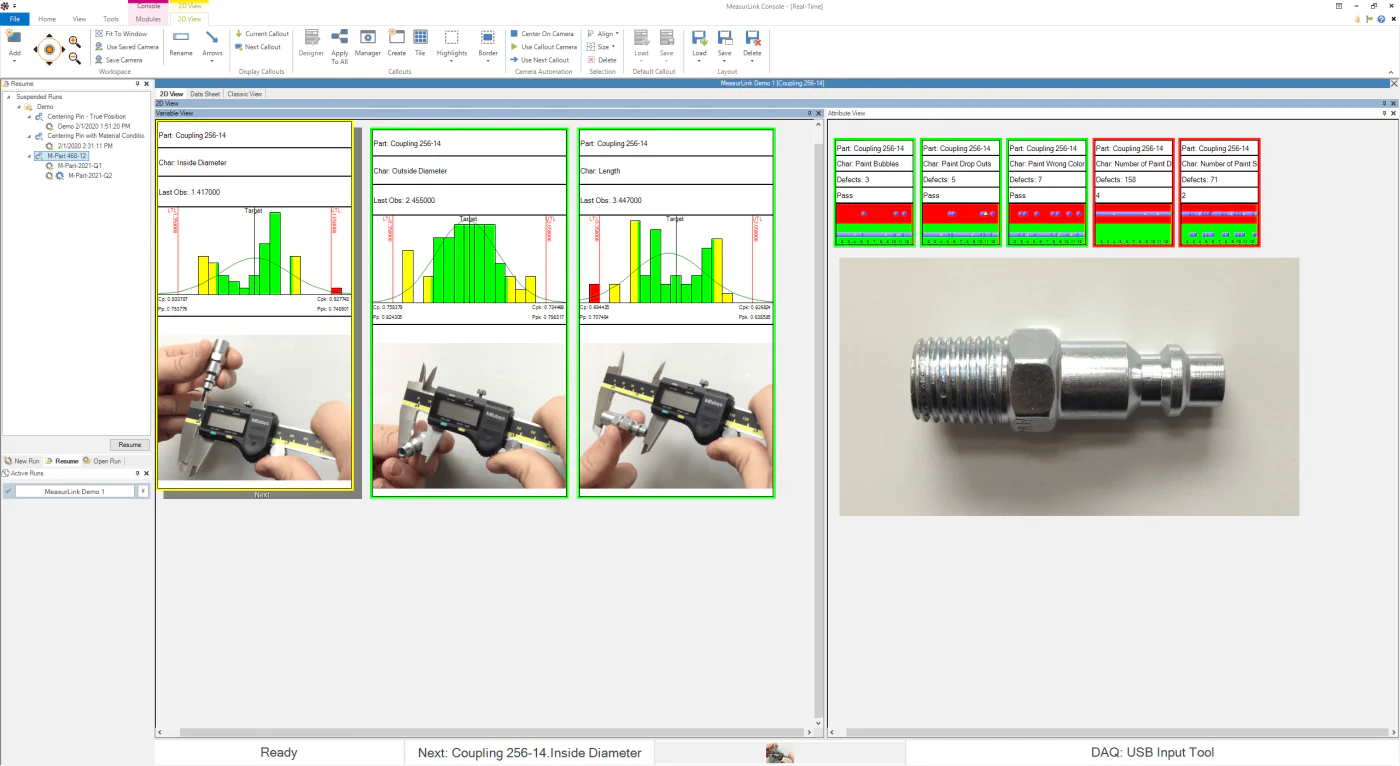

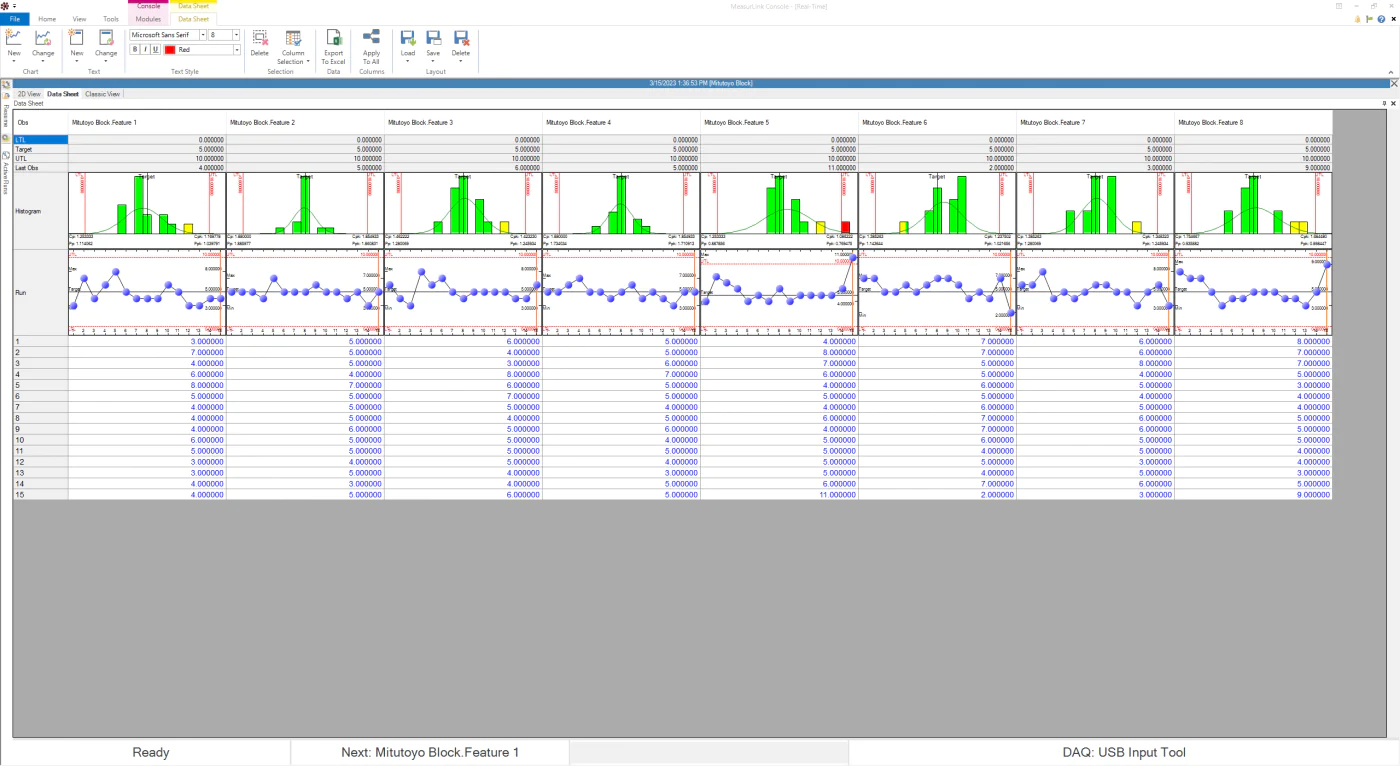

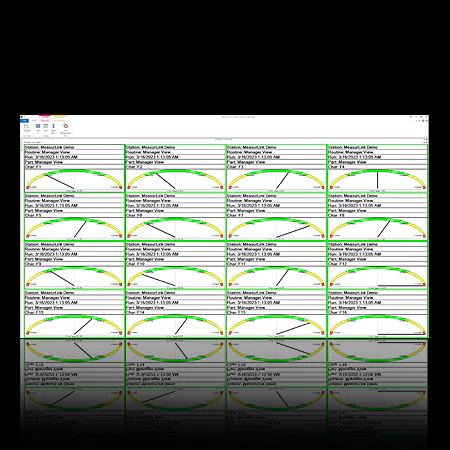

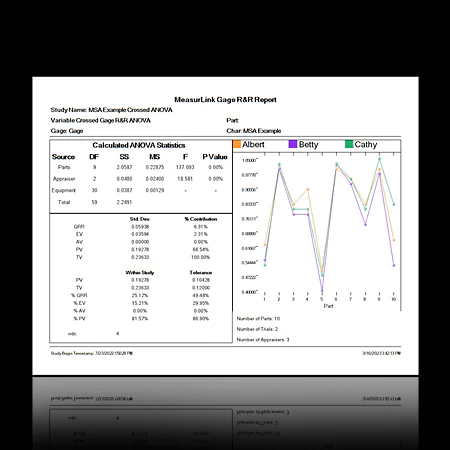

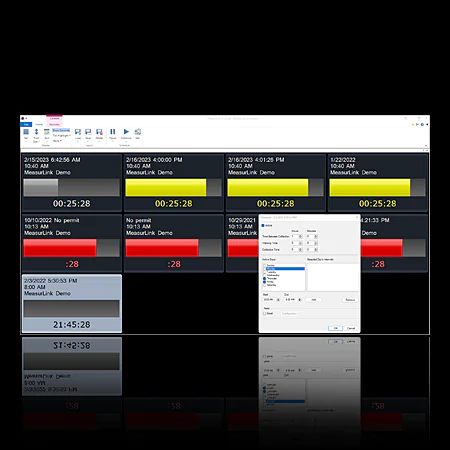

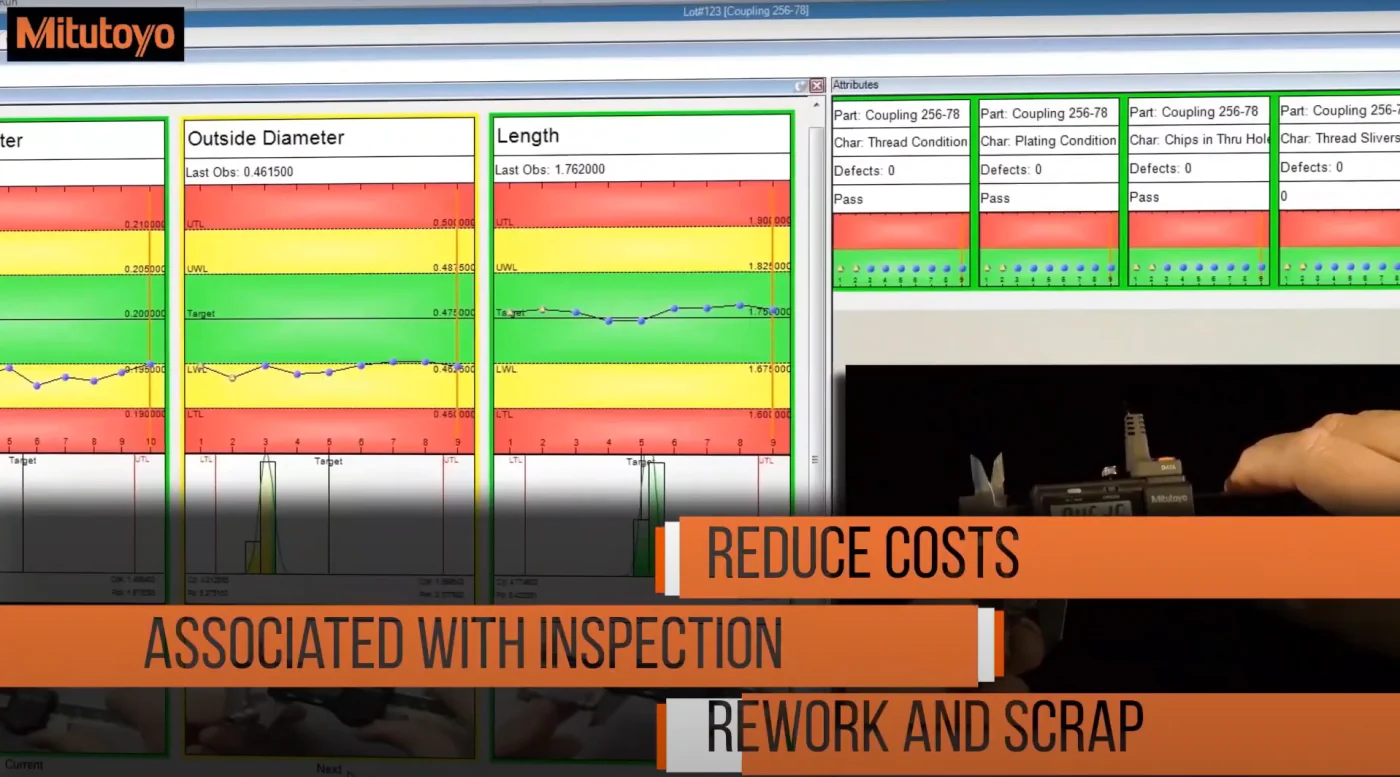

MeasurLink combine la collecte de données en ligne en temps réel avec des graphiques et analyses SPC en temps réel pour les opérateurs et des rapports et alertes de contrôle qualité/superviseur en temps réel pour l'ensemble de votre système de fabrication. MeasurLink est conçu pour les réseaux intégrés afin de créer un système de partage d'informations de qualité qui comprend une solution de métrologie complète pour votre entreprise.

![]()

Réduisez les coûts associés à l’inspection, au remaniement et à la mise au rebut

![]()

Assurer la qualité des pièces et la cohérence

![]()

Augmenter la visibilité des données et l'accessibilité

![]()

Augmenter la facilité d’utilisation pour les inspecteurs dans tous les environnements

![]()

Réduisez les défauts de fabrication grâce à l’utilisation du SPC en temps réel

MeasurLink® 10 est désormais disponible avec davantage de moyens pour rendre l'analyse des données de mesure plus facile, l'inspection plus efficace et de meilleures façons de trouver et d'éliminer les sources de variation !

Nouveautés

MeasurLink 10 s'appuie sur l'architecture existante de MeasurLink 9,

qui a bénéficié d'une utilisation record des licences au cours de sa durée de vie en tant que version actuelle !

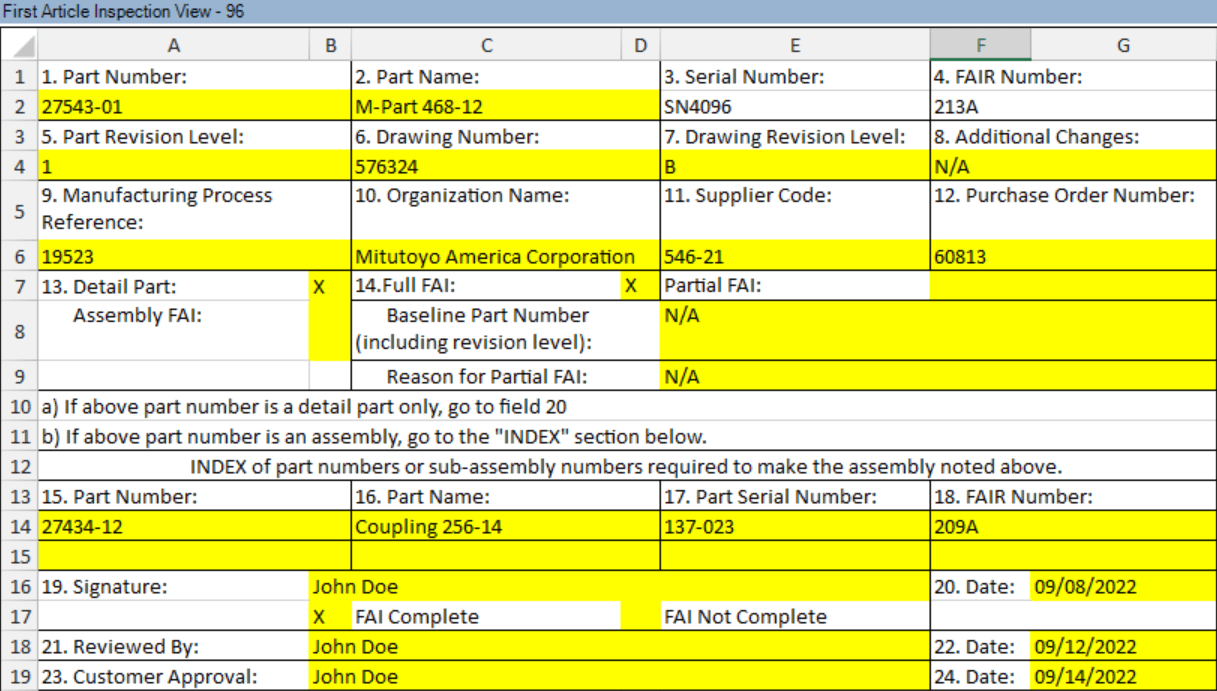

> AS9102 Inspection du premier article

Fournit une approche claire et concise pour compléter les rapports d'inspection du premier article avant le processus de fabrication. Comprend les formulaires 1, 2 et 3. Exportation au format Excel ou PDF.

Caractéristiques des nouveaux produits en temps réel

>Lorsque le module est fermé et que des parcours sont encore actifs, l'utilisateur aura la possibilité de sauvegarder la présentation de tous les parcours actifs en même temps, au lieu d'être invité à le faire individuellement pour chaque parcours. Cela permet de fermer le module plus rapidement et plus efficacement.

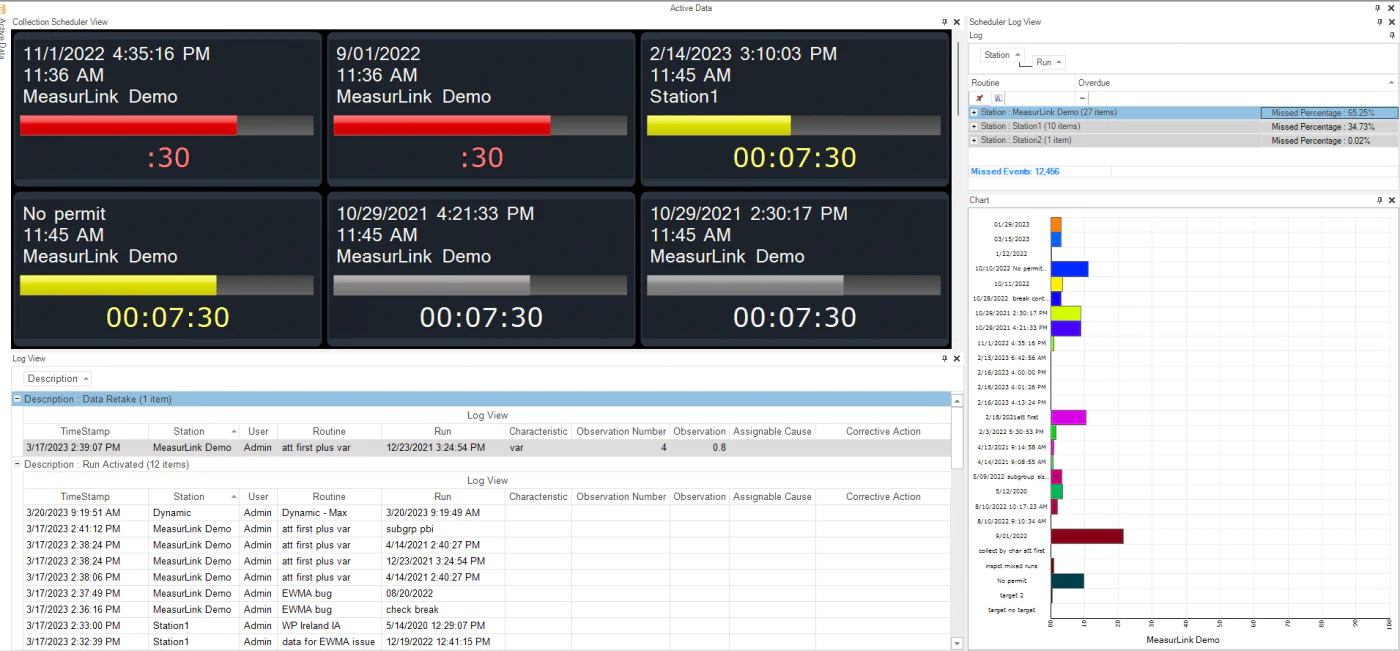

>Le planificateur de collections est inclus dans l'édition Real-Time et ne nécessite plus de licence. L'analyse des données manquantes est disponible dans le gestionnaire de processus.

>Les rapports d'inspection du premier article (FAIR) de la norme AS9102 sont désormais disponibles sous la forme d'un formulaire à remplir et à imprimer. Cela comprend la mise en place, la collecte de données et l'établissement de rapports à l'aide des formulaires 1, 2 et 3.

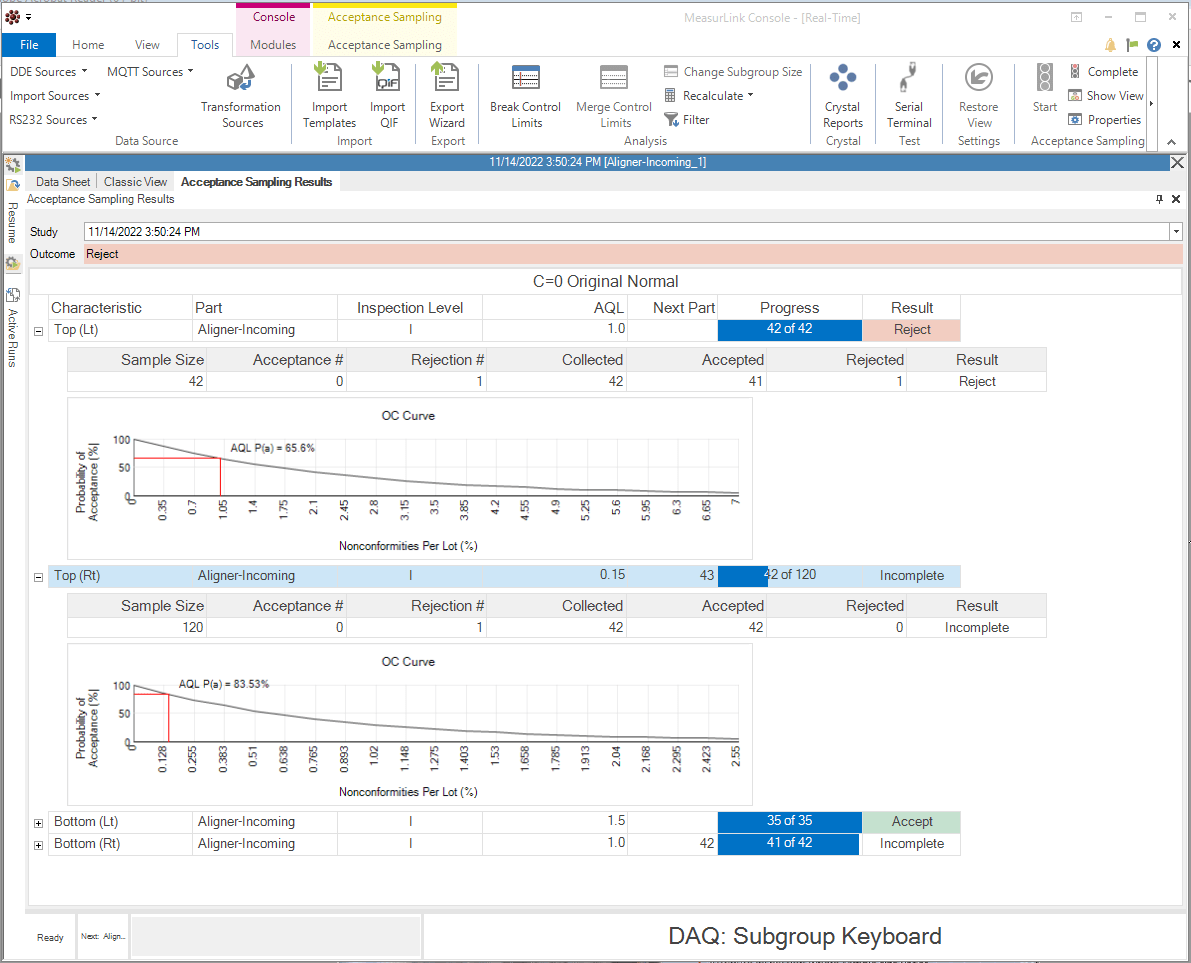

>Soutien à l'échantillonnage d'acceptation pour les directives C=0 ou Z1.4 afin de déterminer les quantités et les résultats de l'inspection pour décider d'accepter ou de rejeter l'ensemble du lot de matériaux. Affiche les courbes d'OC pour l'évaluation des risques. Exportation vers Excel ou PDF.

>Un seul point de données peut être supprimé au milieu d'une analyse, que ce soit en temps réel ou dans l'analyseur de processus. Les données marquées seront supprimées ou ajustées au nouvel ordre des données en fonction des propriétés de cette balise, et les statistiques seront mises à jour au moment de la suppression. Les statistiques seront mises à jour au moment de la suppression. Notez que cette suppression est permanente et irrécupérable.

> Missed Inspection View and Metrics

View metrics based on run, routine, station, and time for missed data collections using Process Manager.

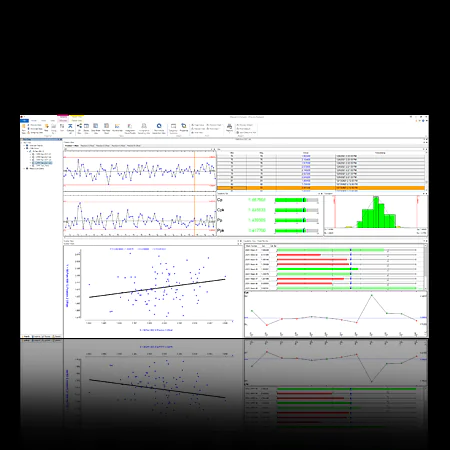

Process Analyzer New Product Features

>Box Plot analysis capabilities have been added to the Capability View.

>Acceptance sampling for C=0 and Z1.4 standards on historical data.

>Support for AS9102 First Article Inspection Reports – viewing, printing, editing, export to Excel or PDF.

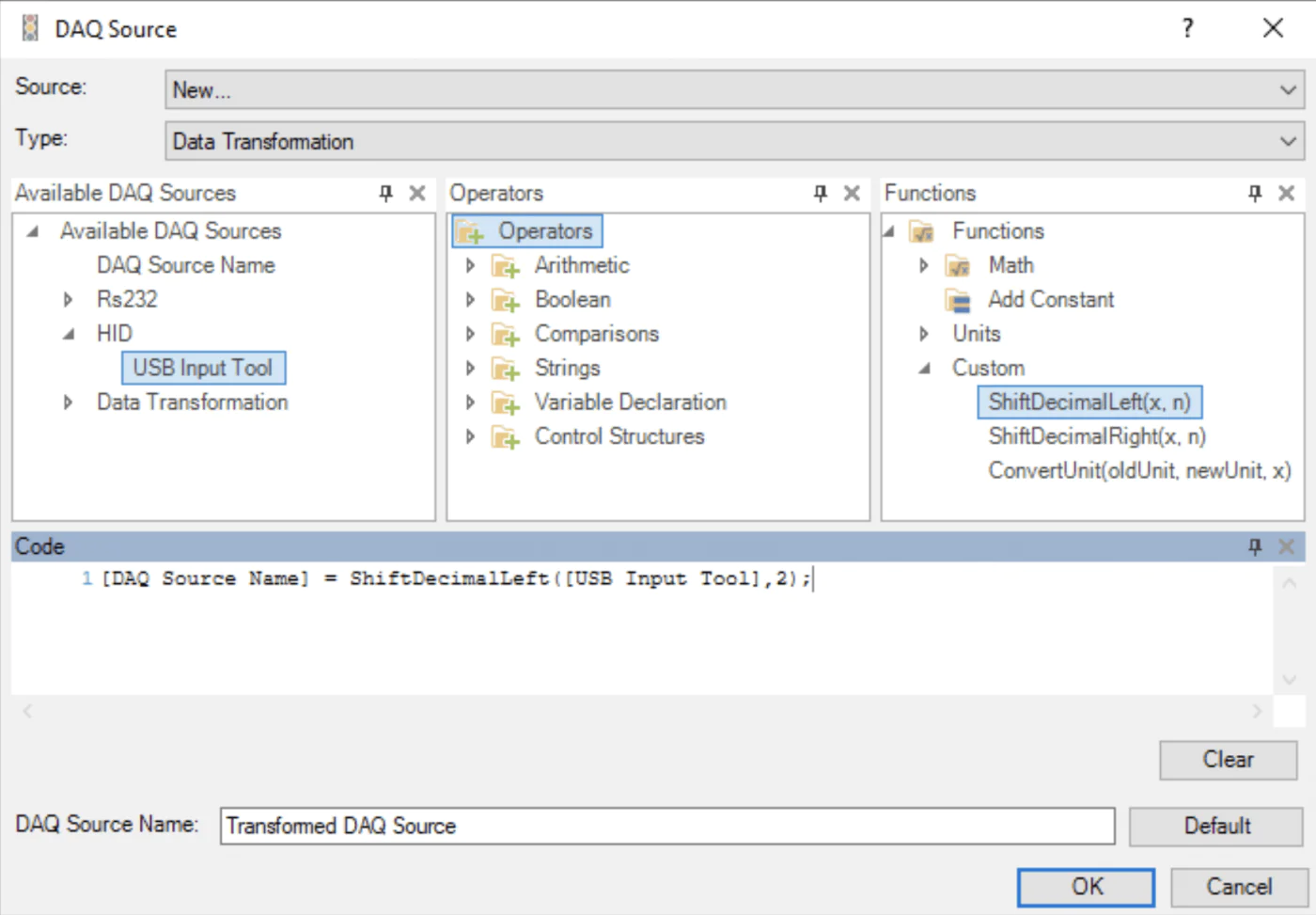

> Data Transformation

Transform data from measurement sources before storing and displaying results. This function can convert units and shift decimal points to make data collection even easier.

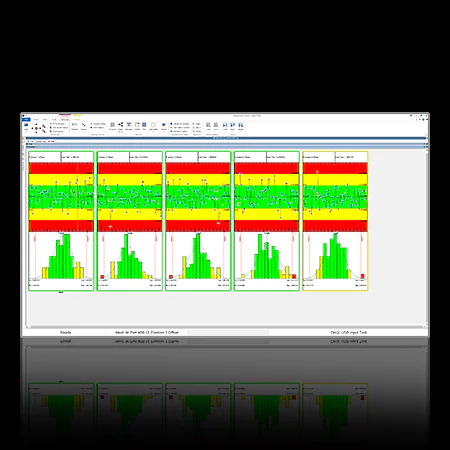

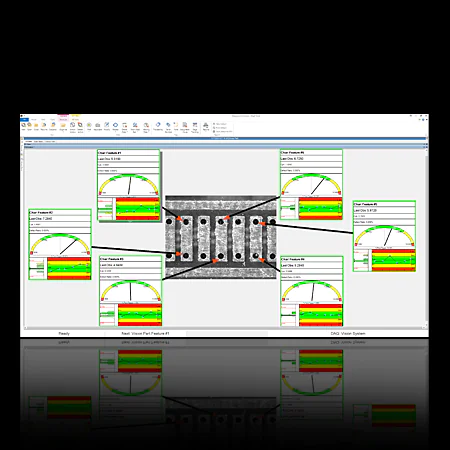

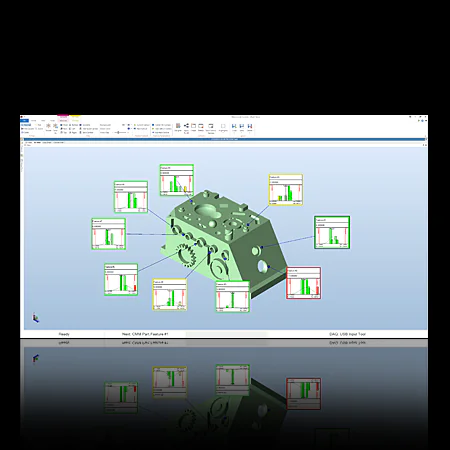

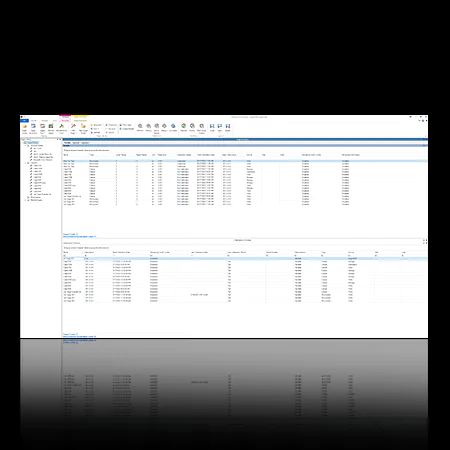

Designed to collect data at the point of manufacture, operators can be alerted of trends, cycles, and nonconformance as soon as they occur. A customizable user interface allows the user nearly infinite ways to view information specific to that process. MeasurLink Real-Time has the ability to connect and acquire data from virtually any measuring device. It supports the full range of metrology technology, including calipers, micrometers, indicators, CMMs, vision systems, and more.

Real-Time Standard - Features & Benefits

>User Friendly

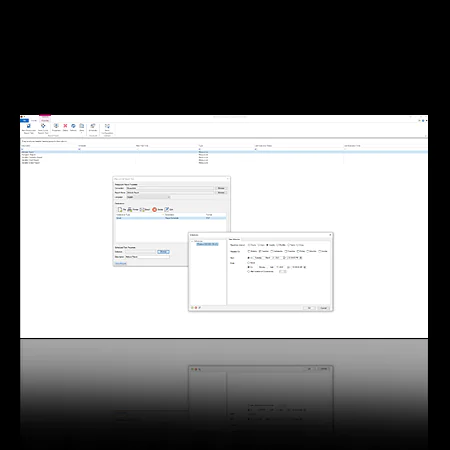

Click a gauge button and watch the charts update in real time. This helps the operator stay on top of the process. Begin collecting data in minutes with the newly designed Inspection Wizard.

>Part Pictures

View scanned blueprints, and digital photographs at a glance. On-screen guided sequencing keeps the operator moving to the right feature.

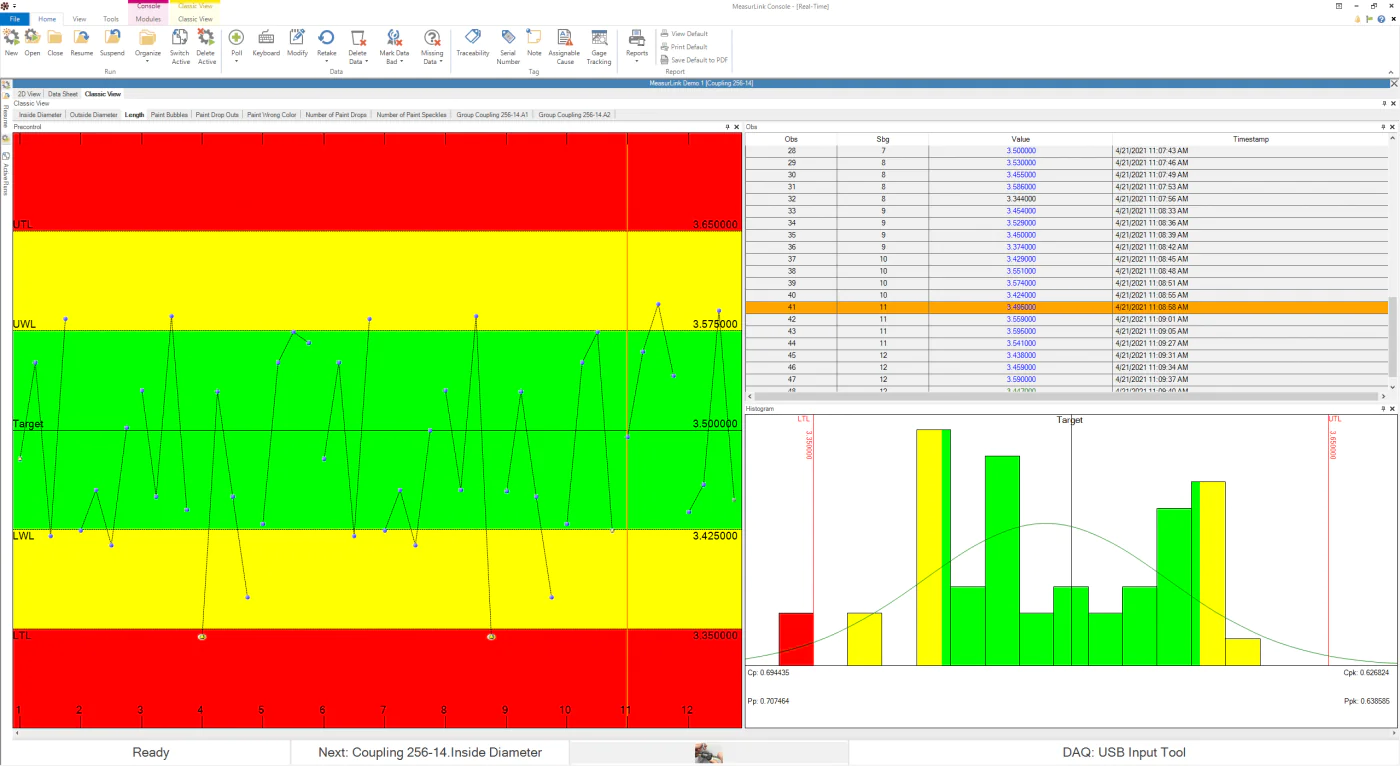

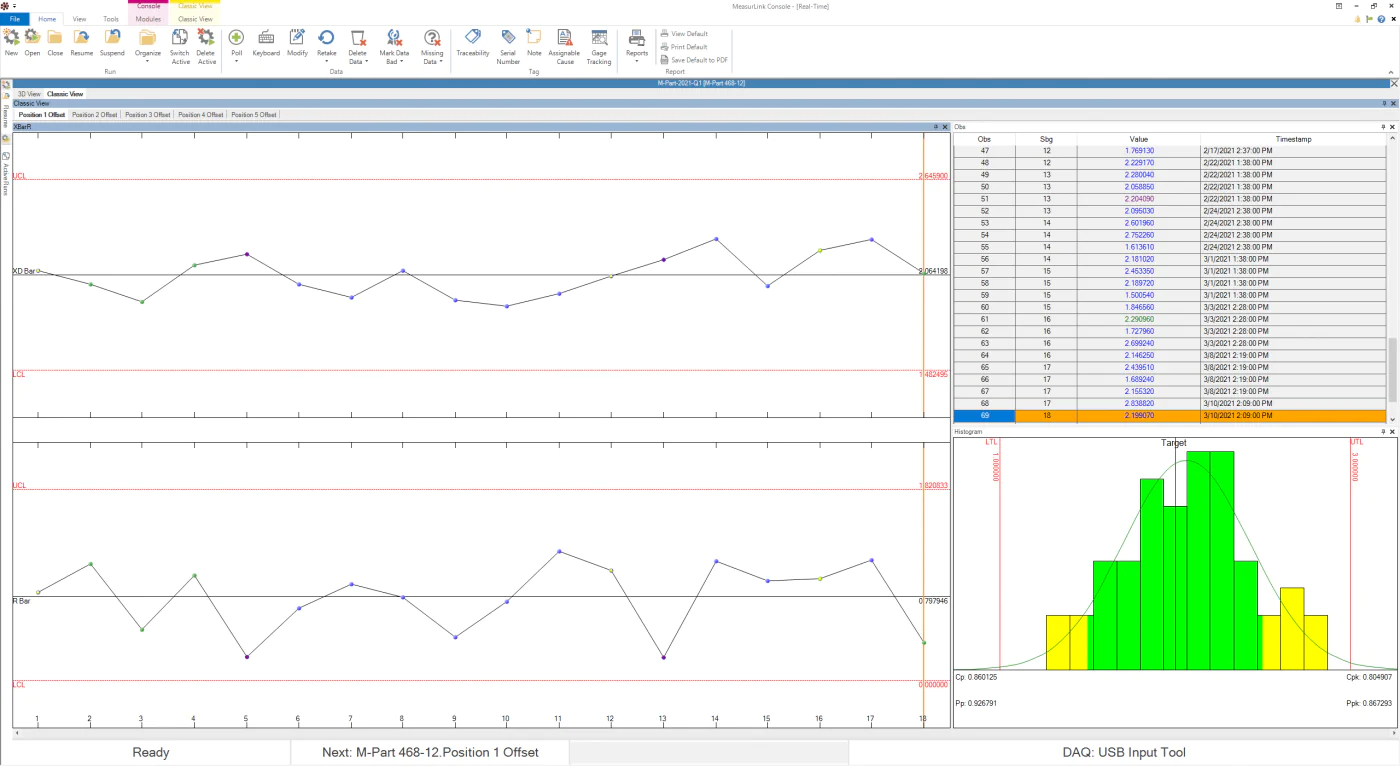

>Comprehensive SPC

Easy-to-use Control Charts, Histograms, Capability, Detailed statistics, Assignable Causes, Corrective Actions, and Traceability all make this software “best in class”.

>Variable Collection Frequency

Allows characteristics of the same routine to be measured at different intervals while maintaining appropriate prompted guided sequencing.

>Multimedia Aids

Attach movies (AVI, MOV, MPG), sound (WAV), and images (BMP, JPG, TIF) to parts, routines, or individual characteristics as instructional aides for an operator.

>Revision History

Track specification adjustments and preserve historical data.

>Data Acquisition and Input

Collects data from digital micrometers, calipers, indicators, bore gauges, etc. The keyboard entry is a snap making it possible to collect data for one or even a million parts. Begin collecting data in 60 seconds with a “Quick Run” by defining features, tolerances, and input methods. There is also flexible data input by collecting data by feature, part, etc.

>Variable and/or Attribute Data

Collect dimensional data (length, width, height, outside diameter, inside diameter weight, etc.). Supports derived features (calculations for run out, volume, true position, etc.).

Mix your dimensions and non-conformance in the same Inspection Routine. Track defects and defectives along with your dimensional data. Collect data from visual inspections (burrs, cracks, dents, missing holes, etc.) to determine the fitness of a part.

Track failures using a go/no-go style or count the defects on a characteristic to determine if a part is defective. There is complete flexibility to study the characteristics individually and in groups.

>Crystal and Flexible Reporting

Create your own customized Crystal Reports for use with Part or Run data.

Build report templates with company logos and free-form text. Users can also select and position chart types to customer specifications.

>Engineering Specifications

Attach drawings to parts, routines, or individual characteristics for viewing.

Most file formats are supported as an attachment (e.g. Word, PDF).

>Data Tests

Full support of Western Electric and Nelson Tests for pattern recognition in control charts (e.g. extreme point, trend, stratification, oscillation, etc.)

along with various alerts for each failed test.

>Time-Stamped Data

All observation data is marked with the date and time from the computer clock.

>Corrective Plans

Operators choose corrective action as applied to the part or process.

Multiple corrective actions can be applied to any subgroup. Empower the operator to build on the existing Corrective Action list.

>Forced Assignable Cause

Force Assignable Cause Tags are possible during collection if the process is out of control. Empowering the operator to build on the existing pick list.

> Acceptance Sampling

MeasurLink's Acceptance Sampling feature calculates the correct number of samples to take and will reject or accept lots based on C=0 or ANSI Z1.4 standards. OC Curves can be displayed for risk evaluation with the possibility to export to Excel or PDF.

Acceptance Sampling New Product Features

>In Routine Library, runs can now be created at other stations than the user is currently on, eliminating the requirement for a setup person to be at the station to create a run.

>A new property for Criticality has been added to the revision level of a characteristic in the Part Library. This will support functionality for processes such as acceptance sampling.

>In Station Library, a DAQ source can be enhanced to apply an equation to the data to “transform” it into more usable data within MeasurLink. This transformed DAQ source will allow for simpler handling of unit conversions, addition or shifting of decimal places, and can perform similar functions as derived characteristics, such as conditionally calling external programs. Common transformation functions have been built into Station Library for users to take advantage of, including functions to shift decimal positions left or right and convert units using the long-standing Unit Manager function of the Support Center.

>Usability improvements to the libraries were implemented to make options easier to find and use.

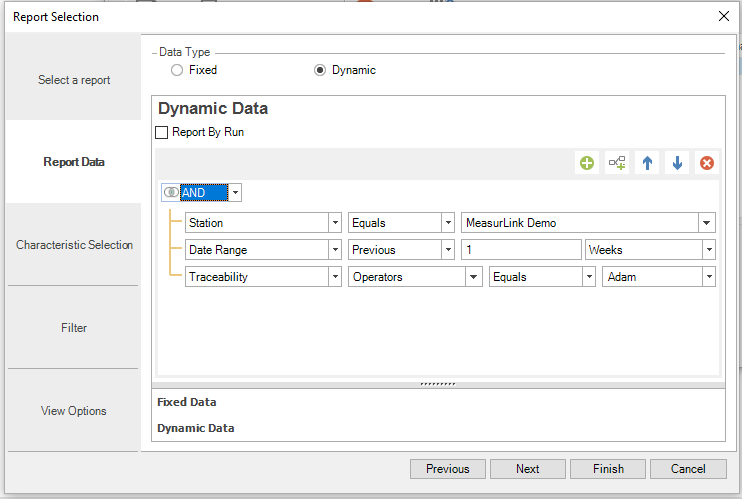

> Dynamic Run Selection

This supports functionality for enhanced reporting. It gives users the ability to report on multiple runs across separate stations, parts, and routines based on filter criteria. Output all runs matching filter criteria to a single report, or an individual report for each run.

Dynamic Run Selection - New Product Features

>The MeasurLink user experience has undergone an update in visual presentation. Icons, window themes, and workspaces have been modified to provide a flatter feel, utilizing fewer but more consistent colors throughout. Additionally, chart backgrounds, plot points, and histogram bins have changed the default color scheme to remove the previous gradient.

>Support has been added for acceptance sampling methods of data collection. Standard AQL methods supported are C=0 (Squeglia) and ANSI Z1.4. The module will allow for runs that are specific to SPC or acceptance sampling, or they can be combined to use the same data within a run for both purposes. Users can also leverage historical data to create sample studies.

>Support has been added for AS9102 First Article Inspection methodologies. This includes setup, data collection, and reporting using the standard form.

>Active Input device commands can now be sent to MeasurLink from HID devices, such as using a barcode scanner to open an inspection routine.

>When the database version upgrade dialog displays, primarily after a service pack has been applied, the user now has the option to change the connection so as to avoid updating a database that should not be updated (for example, to allow switching from production to a test or QA database).

>The concept of run type has been added with values of SPC run (this is the run structure of previous versions of MeasurLink), First Article Inspection Results, Acceptance Sample, or a combination of the three. Specific icons have been added for each run type, and appropriate trees can be grouped by this new type as well.

>Support has been added for the MQTT data transfer protocol (input only).

>More robust filtering of trees in the Report Scheduler, Process Analyzer, and Process Manager has been included. A more advanced user experience provides the ability to achieve more complex and granular tree displays, making it easier to identify and work with only the desired data. Filter criteria include multiple logical operands, more filtering types, and grouping controls to allow for advanced order of operations. Filters can be inclusive or exclusive.

>XBar/R and XBar/S charts can be converted to “rainbow” charts by including the sigma zone lines and optionally adding a color scheme within the zones.

>A new report page for displaying the electronic signature history of a run has been added to the Characteristic Independent section of MeasurLink reports.

>When previewing or printing a chart in Probability View or Classic View that contains filtered data, the filter criteria are displayed at the top of the chart.

> MQTT JSON Device

Supports machine-to-machine communication protocol for industrial automation. Similar to RS-232 devices, the measurement, traceability, and serial number can be collected.

MeasurLink General Features & Enhancements

>The MeasurLink user experience has undergone an update in visual presentation. Icons, window themes, and workspaces have been modified to provide a flatter feel to the UI, utilizing fewer but more consistent colors throughout. Additionally, chart backgrounds, plot points, and histogram bins have changed the default color scheme to remove the previous gradient.

>Support has been added for acceptance sampling methods of data collection. Standard AQL methods supported are C=0 (Squeglia) and ANSI Z1.4. The module will allow for runs that are specific to SPC or acceptance sampling, or they can be combined to use the same data within a run for both purposes. Users can also leverage historical data to create sample studies.

>Support has been added for AS9102 First Article Inspection methodologies. This includes setup, data collection, and reporting using the standard form.

>Active Input device commands can now be sent to MeasurLink from HID devices, such as using a barcode scanner to open an inspection routine.

>When the database version upgrade dialog displays, primarily after a service pack has been applied, the user now has the option to change the connection so as to avoid updating a database that should not be updated (for example, to allow switching from production to a test or QA database).

>The concept of run type has been added with values of SPC run (this is the run structure of previous versions of MeasurLink), First Article Inspection Results, Acceptance Sample, or a mixed type (combination of the first three). Specific icons have been added for each run type, and appropriate trees can be grouped by this new type as well.

>Support has been added for the MQTT data transfer protocol (input only).

>More robust filtering of trees in the Report Scheduler, Process Analyzer, and Process Manager has been included. A more advanced user experience provides the ability to achieve more complex and granular tree displays, making it easier to identify and work with only the desired data. Filter criteria include multiple logical operands, more filtering types, and grouping controls to allow for advanced order of operations. Filters can be inclusive or exclusive.

>XBar/R and XBar/S charts can be converted to “rainbow” charts by including the sigma zone lines and optionally adding a color scheme within the zones.

>A new report page for displaying the electronic signature history of a run has been added to the Characteristic Independent section of MeasurLink reports.

>When previewing or printing a chart in Probability View or Classic View that contains filtered data, the filter criteria are displayed at the top of the chart.

> Request your Full Version

60-Day Free Trial - Today!

The software included in this Mitutoyo FREE TRIAL can be used for 60 days after installation.

Available in 17 different languages.

Please let us know your contact details.

Database Management System (DBMS) Requirements

MeasurLink 10 ships with a copy of Microsoft SQL Server 2019 Express Edition. This can be for a standalone or a workgroup installation, although the Express version of SQL Server is not recommended for customers with more than 5 licenses.

MeasurLink 10 also supports the following Microsoft SQL Server versions:

• Microsoft SQL Server 2019 all editions

• Microsoft SQL Server 2017 all editions

• Microsoft SQL Server 2016 all editions

• Azure Microsoft SQL Server

Operating System Requirements

All MeasurLink 10 products are supported on the following Microsoft Windows Operating System versions:

• All Windows 11 64bit versions

• All Windows 10 64bit versions

By requesting the Mitutoyo 60-DAY MEASURLINK 10 FREE TRIAL you agree that an authorized representative of Mitutoyo Europe will contact you via email to provide you with a download URL for your 60-DAY MEASURLINK 10 FREE TRIAL. This requires completeness and correctness of your contact information, especially email and your telephone number.

Data protection is a matter of trust – and your trust is important to us. We – Mitutoyo Europe GmbH – respect your privacy and personal sphere. The protection, lawful collection, processing, and use of your personal data are important considerations to us. In order for you to feel secure when visiting our website, we strictly observe the legal regulations when processing your personal data and would like to inform you about our data collection and use of data.

Please refer to our Privacy Policy.

The General Terms and Conditions of Licensing for the Use of Computer Programs (Software) (GTB) of Mitutoyo Europe GmbH are applied to this offer.

Download the NEW Measurlink 10 Introduction Leaflet

Related